Transform Your Plant Performance

Reducing Energy Consumption Around The World

Patented Clean Techology To Increase Energy Efficiency & Reduce Emissions

Would You Like To

Improve process stability and reduce unplanned downtime

Cut maintenance costs

Reduce greenhouse gas emissions

Eliminate the back pressure in condensate lines and reduce the steam venting into the atmosphere

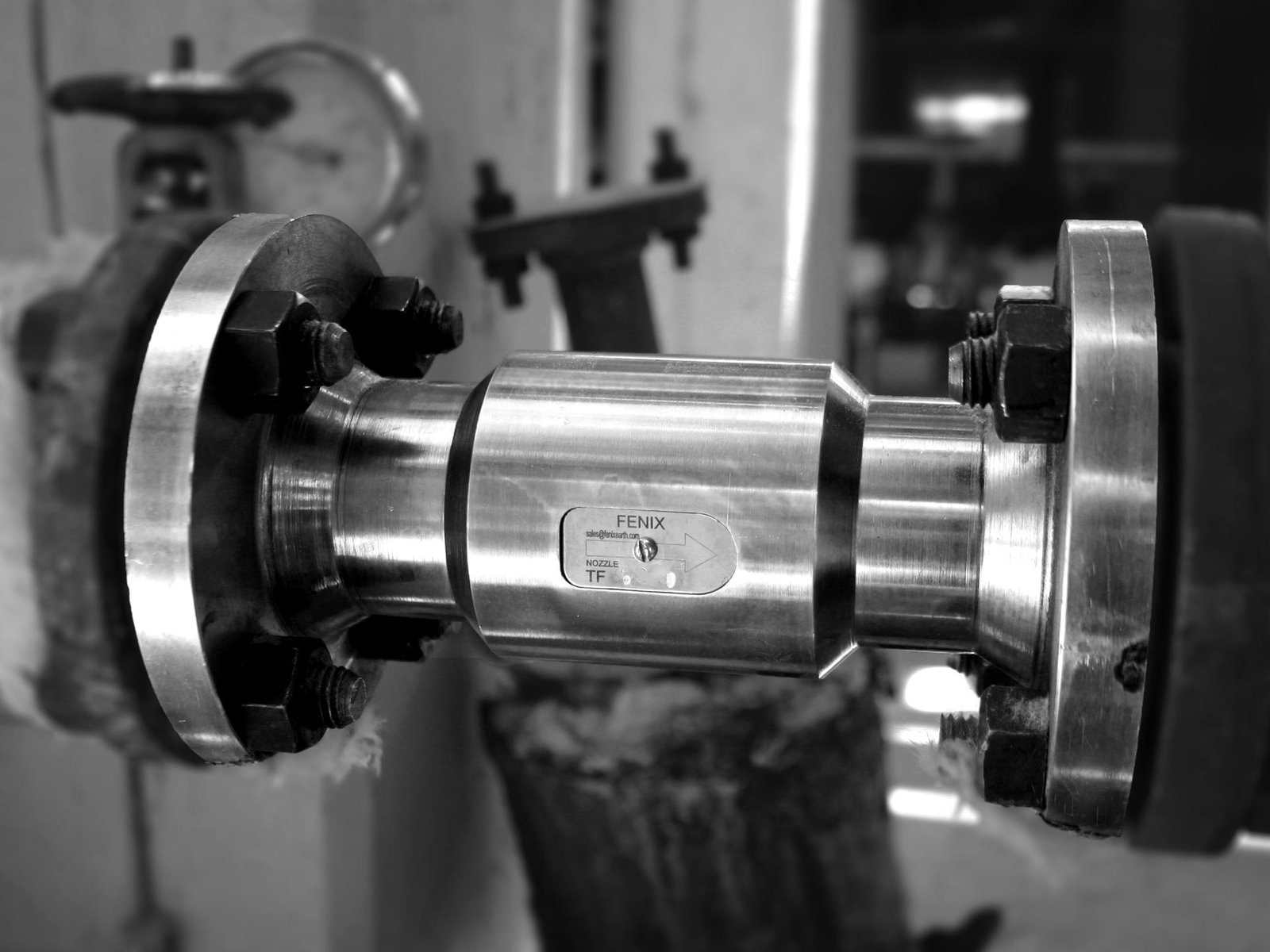

What Is A Steam Trap?

In steam systems condensate is formed in the distribution system while the steam travels through the pipework and is various heat exchangers and applications of the process. It is imperative that this condensate is removed and returned to the boiler house.

A steam trap is a device to efficiently remove the condensate from a steam system without allowing live steam to escape.

Why Hydronamic Technology?

Mechanical traps (ball float, inverted bucket, thermodynamic, free float and thermostatic) are the most conventional technologies but have moving parts that will fail. Hydrodynamic traps use a new technology based on fluid dynamics and have no moving parts to fail.

How Hydrodynamic Steam Traps Work

The Fenix hydrodynamic steam traps have no moving parts. The condensate forms a seal at the inlet to the venturi nozzle that prevents the steam passing. The venturi nozzle uses the flashing steam to create a back pressure in the nozzle that regulates the flow through the nozzle. Because the amount of flash varies with changes in the process the capacity of the nozzle self regulates to allow the hydrodynamic traps to work on variable loads.

60 Day Free Steam Trap Trial

Take advantage of our free 60 day steam trap trial and see for yourself the benefits of having fenix steam traps operating in your plant.

What Is A Condex System?

The most effective waste heat recovery system available, tailored to maximize your efficiency, reduce emissions, reduce operating costs and increase plant capacity.

The ConDex Energy Recovery System recovers massive amounts of thermal energy that is otherwise lost in flue gas from boilers, turbines, ovens, dryers, etc., and returns it directly to your process and operations.

Energy Recovery Perfected – And Guaranteed!

Awarded two Clean-Tech patents, the The ConDex System utilizes specialized metallurgy, and proprietary design engineering to significantly enhance the heat transfer process. It recovers over 30% more energy versus other heat recovery systems.

Smaller Footprint – Scalable to Every Configuration – 95%+ Boiler Efficiency

The ConDex System is more compact than standard systems, and will not interfere with your existing processes.

Single ConDex units can be customized to recover energy from one or multiple-stack sources on a fully modulating basis.

By lowering exhaust gas temperatures below their dew point, ConDex Systems recover both sensible and latent heat, making 95%+ boiler efficiency attainable.

ConDex Condensing Economizers

Fill out our Boiler Intake form Today!

Download the PDF form below to review and fill in your answers today. Send it back to us at stuartbevan@enerop.co.uk and we will be happy to get things moving with you!

What Our Customers Say

“The ConDex System has paid for itself several times over since its installation. The weekly steam requirement for the make-up water has been cut from 800,000 lbs/hr to 400,000 lbs/hr, providing significant energy savings and emissions reduction. We love it.”

“The ConDex System has paid for itself several times over since its installation. The weekly steam requirement for the make-up water has been cut from 800,000 lbs/hr to 400,000 lbs/hr, providing significant energy savings and emissions reduction. We love it.”