The ConDex Condensing Economizer System

Lower your operating costs while increasing capacity with unprecedented energy efficiency, emissions reductions and fuel savings all in one solution. We engineer, manufacture and integrate custom ConDex Condensing Economizer Systems which allow our customers to put waste energy back to work.

What Is A Condex System?

The most effective waste heat recovery system available, tailored to maximize your efficiency, reduce emissions, reduce operating costs and increase plant capacity.

The ConDex Energy Recovery System recovers massive amounts of thermal energy that is otherwise lost in flue gas from boilers, turbines, ovens, dryers, etc., and returns it directly to your process and operations.

Energy Recovery Perfected – And Guaranteed!

Awarded two Clean-Tech patents, the The ConDex System utilizes specialized metallurgy, and proprietary design engineering to significantly enhance the heat transfer process. It recovers over 30% more energy versus other heat recovery systems.

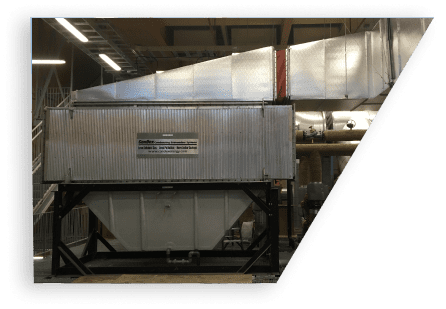

Smaller Footprint – Scalable to Every Configuration – 95%+ Boiler Efficiency

The ConDex System is more compact than standard systems, and will not interfere with your existing processes.

Single ConDex units can be customized to recover energy from one or multiple-stack sources on a fully modulating basis.

By lowering exhaust gas temperatures below their dew point, ConDex Systems recover both sensible and latent heat, making 95%+ boiler efficiency attainable.

The ConDex ADVANTAGE

ConDex condensing economizers are proven to achieve efficiency levels that are impossible to reach with traditional economizers. The patented ConDex System offers many advantages over traditional energy recovery methods

30%+ More Energy Recovery

The ConDex System uses recovered waste energy to heat water or working fluids upwards of 95 C / 200 F.

Faster Payback

The remarkable increase in efficiency means that your ConDex System pays for itself in less time – often within a year or two.

Cleaner Water

The unit won’t contaminate your process water. Unaffected water exiting the exchanger is ready for sanitary processes without need for costly chemical treatments.

More Water Recovered

Water is created in any combustion process and approximately 18% of natural gas exhaust is water vapor – the ConDex system will recover most of it for you to reuse.

Lower C02 Emissions

Lower energy consumption and increased emissions captured in the ConDex system means fewer harmful emissions, including NOx, SOx and CO2 greenhouse gases.

Meet Your ESG Obligations

By increasing plant efficiency and reducing emissions, ConDex Condensing Economizer Systems also help organizations address their Environmental, Social and Governance (ESG) obligations.

Lower Maintenance, Repair and Replacement Costs

More energy recovery means less demand on your fired equipment. In addition to lower operating costs, you’ll enjoy less downtime too.

Increase Plant Capacity

The efficiencies you get from a ConDex System let you increase output without increasing your budgets.

What we do

Simply put, we work with our customers to reduce their energy consumption by recovering waste heat and seamlessly integrating that energy back into their processes.

Custom Energy Recovery Systems

The ConDex Condensing Economizer System is tailored to maximize energy recovery, cost savings and plant capacity. Our end-to-end solution means we engineer, manufacture, and support your system.

Process Integration

We ensure the smooth integration of your recovered waste energy with your existing heating processes.

Full Package Solution

We can supply all necessary equipment, including the control system and programming. You won’t find a condensing economizer capable of the same performance anywhere else.

Customer Support

We are just a phone call away to support your energy recovery systems, from initial start-up procedures and troubleshooting to maintaining the highest levels of efficiency and cost savings.

How the ConDex System Recovers 30%+ More Heat

High Heat Transfer Capabilities

Simply put, we made the ConDex System capable of handling more extreme conditions than standard heat recovery systems. Proprietary metallurgy and a unique finned-tube configuration allow ConDex Systems to recover more heat from exhaust gas at temperatures in excess of 1000°F.

Condenses Water Vapour in Exhaust Gas

The high heat transfer ability of ConDex Systems cools exhaust gas below its dew point to recover a massive amount of energy that would otherwise be wasted. The heat recovered at 980 Btu/lb (544.88Kcal/kg), saves one cu.ft. (.28 cubic metres) of natural gas.

Corrosion Resistance

The ability to recover more energy by cooling exhaust gases to the point of condensation is facilitated by the high corrosion-resistant properties of the metals used in ConDex exchangers. They also require less maintenance, fewer repairs and have longer operating life compared to standard systems.

Smaller Footprint - Bigger Performance

The cylindrical ConDex System is dramatically smaller but far more efficient than standard systems. But its efficient size has no impact on the exhaust source, and it operates within with your existing processes.

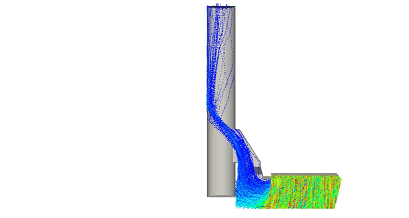

Patented Reverse-Flow Design

ConDex Systems are uniquely capable of cooling exhaust gases below their dew point due to their innovative, Clean-Tech patented reverse-flow design, which protects boilers from the condensate and the corrosion it causes.

Guaranteed Performance

Your ConDex system’s energy recovery performance is guaranteed. And we also guarantee our exchangers against corrosion from flue gas condensation.

ConDex Condensing Economizers

Fill out our Boiler Intake form Today!

Download the PDF form below to review and fill in your answers today. Send it back to us at stuartbevan@enerop.co.uk and we will be happy to get things moving with you!